Factory automation is an important part of any industry. It has been around for many years and it is still developing to make the tasks in a factory easier. The benefits of this system are huge, but there are some challenges that need to be addressed before they become a reality.

What is Factory Automation?

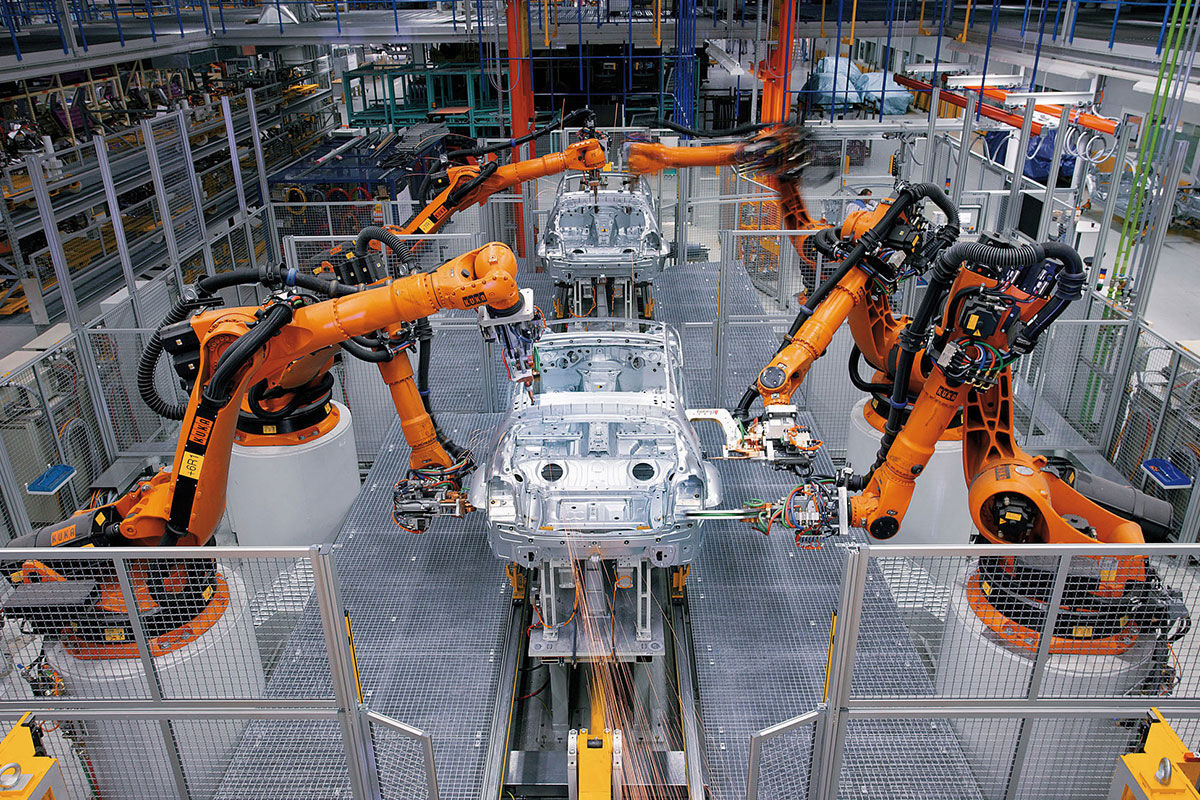

- Factory automation is a system that provides control of the production processes. It integrates hardware and software, which includes PLCs (Programmable Logic Controller), robots, sensors and other devices used in manufacturing.

- Factory automation is an industry that deals with robotic machines. They’re widely used in industries such as automotive, aerospace and medical.

Factory automation is the use of industrial control systems to help manufacturers improve their production processes. This technology helps companies increase efficiency, reduce waste and boost profitability.

Advantages of Factory Automation

- Increase in productivity: Automation systems at factories help in increasing the productivity of the company and reduces human errors.

- Increased quality: With low production costs, increased quality is another advantage of factory automation systems. A good example would be that when a manufacturer uses robots for assembly, they don’t need to worry about any flaws or defects in their products. This brings down the need for continuous quality control and testing of products, which also leads to a significant reduction in costs associated with these processes.

- Cost of automation. The first and foremost challenge for factory automation is the cost involved in implementing this technology. For example, if you have to automate your production line with robots, then it will cost around $10 million. This is a huge investment that needs to be taken care of before starting the automation process.

- Lack of skilled employees: Since this technology involves machines handling heavy tasks like welding and assembling, there is a need for skilled workers who can handle these devices without any problems or errors occurring during the operation process. In fact, companies are struggling right now trying to hire people with such abilities because they are rarer than before due to various reasons like lack of proper training facilities etc., which makes them even more expensive than usual when they do come across one such person who has these skillsets at hand!

The second challenge for factory automation is the lack of skilled workers. Since this technology involves machines handling heavy tasks like welding and assembling, there is a need for skilled workers who can handle these devices without any problems or errors occurring during the operation process.

In fact, companies are struggling right now trying to hire people with such abilities because they are rarer than before due to various reasons like lack of proper training facilities etc., which makes them even more expensive than usual when they do come across one such person who has these skillsets at hand!

Conclusion

It is important for any business owner to keep up with the latest trends and developments in their industry. With so many different options available for you, choosing where to invest your time and money can be difficult. However, by following these tips, you can make sure that you are investing correctly in new technology or equipment that will actually benefit your company.