In today’s world, accurate measurements play a crucial role in various industries, from healthcare and manufacturing to research and development. Instrument calibration services are vital for maintaining the precision and reliability of instruments, ensuring accurate readings and optimal performance.

In this blog, we will explore the significance of instrument calibration services and their impact on different sectors.

1. What is Instrument Calibration?

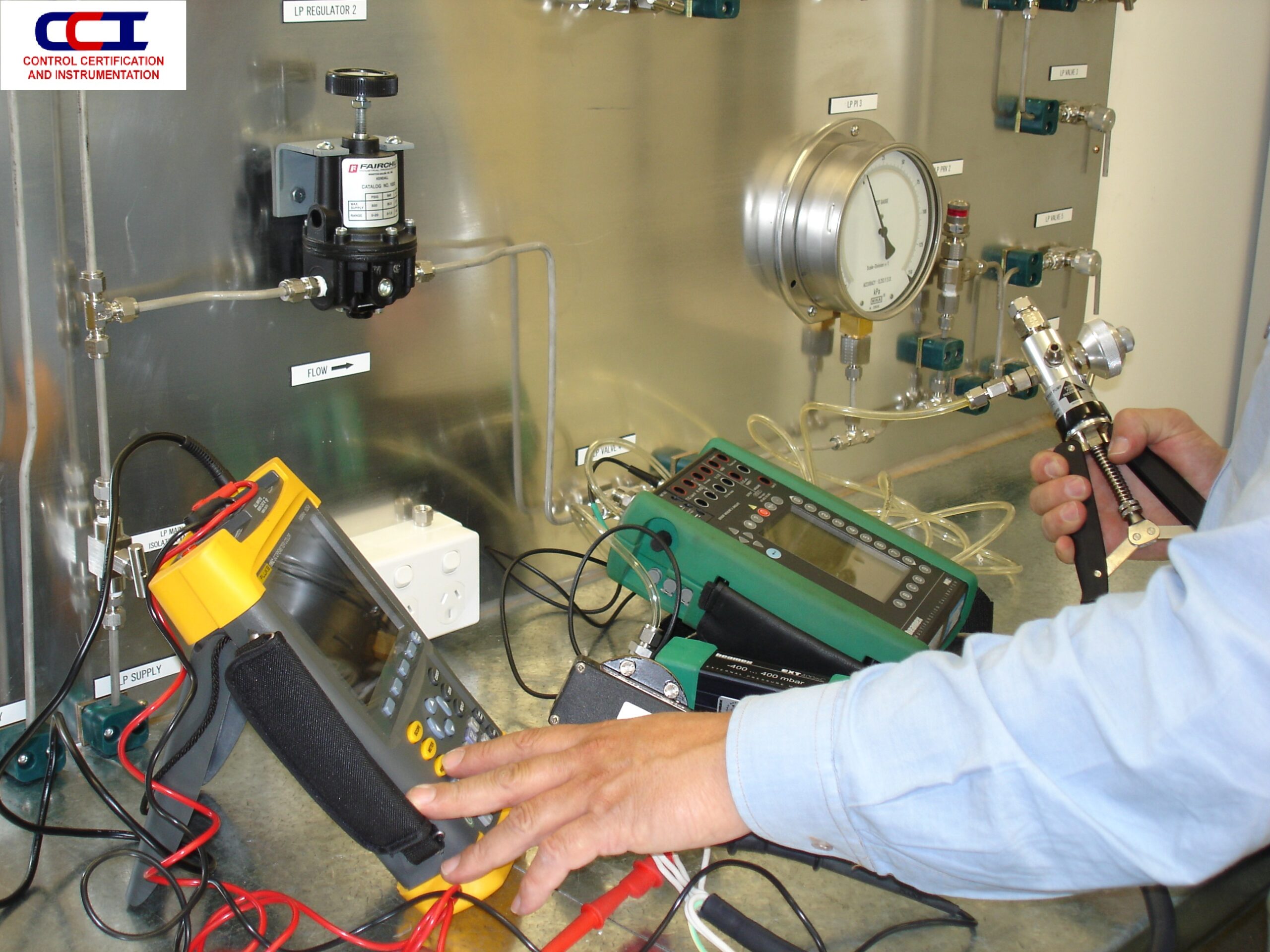

Instrument calibration is the process of comparing the measurements of an instrument against a known reference to determine any deviations or inaccuracies. It involves adjusting the instrument to bring it back to its specified standards.

Calibration is essential because over time, instruments may drift from their original calibration due to environmental factors, regular use, or aging components. Through calibration, the accuracy, consistency, and reliability of instruments are restored, allowing for precise measurements and reliable data.

2. Ensuring Accuracy and Reliability

Accurate measurements are crucial in industries such as healthcare, pharmaceuticals, manufacturing, and engineering. Instrument calibration services ensure that instruments provide precise readings, reducing the risk of errors, safety hazards, and production failures.

By calibrating instruments regularly, professionals can trust the results obtained from their equipment, ensuring quality control and compliance with industry standards. This is particularly important in sectors such as medical diagnostics, where even a small measurement error can have significant consequences for patient care.

3. Compliance with Standards and Regulations

Many industries are subject to strict regulations and standards regarding measurements and quality control. Instrument calibration services help organizations meet these requirements by providing documented proof of calibration.

Regulatory bodies, such as the International Organization for Standardization (ISO), often require instruments to be calibrated regularly to ensure their accuracy and reliability. Calibration certificates serve as evidence that instruments have been properly maintained and meet the necessary standards. Compliance with regulations not only ensures the quality of products and services but also protects the reputation and credibility of the organization.

4. Extending Instrument Lifespan

Regular calibration can extend the lifespan of instruments. By identifying and rectifying any deviations or malfunctions, calibration services can prevent minor issues from escalating into major problems. It helps in detecting and addressing potential failures or inaccuracies before they cause irreparable damage to the instrument.

By investing in instrument calibration services, organizations can reduce maintenance costs, minimize downtime, and maximize the longevity of their equipment. This proactive approach to instrument maintenance ultimately contributes to increased productivity and operational efficiency.

5. Calibration Frequency and Traceability

The calibration frequency of instruments depends on various factors, including the instrument type, its criticality, and the industry requirements. Calibration intervals can range from months to years, with some instruments needing calibration before each use.

Additionally, instrument calibration services ensure traceability by providing calibration records and certificates that detail the calibration process, reference standards used, and measurement uncertainties. This traceability is vital for maintaining the integrity and reliability of measurements throughout the instrument’s lifespan.

Conclusion

Instrument calibration services are indispensable in numerous industries, ensuring accurate measurements, compliance with regulations, and extended instrument lifespan. By entrusting their instruments to professional calibration services, organizations can enhance the reliability of their data, improve quality control, and optimize overall operational performance. Investing in calibration is a proactive step towards precision and excellence in various sectors.